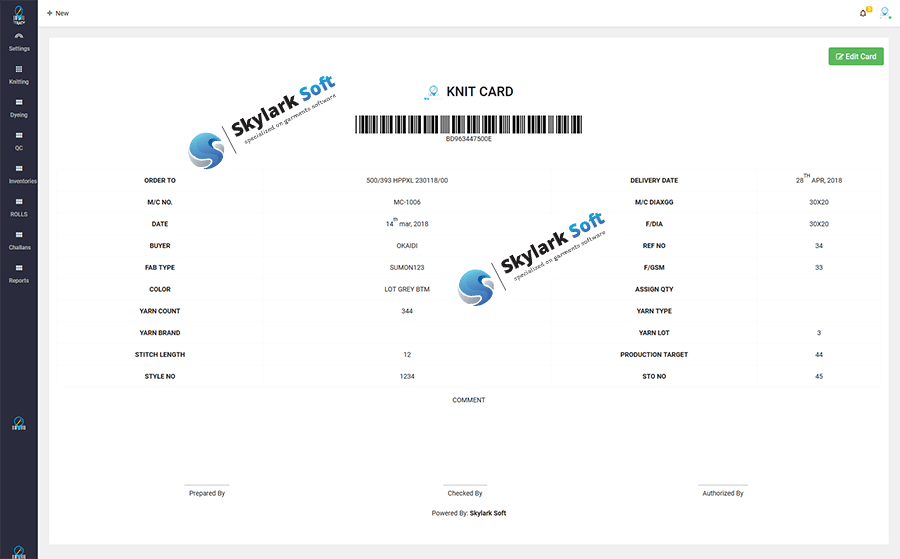

PROKNIT is barcode enabled fabric roll tracking system. We use exclusive labels and ribbons by pressing on fabric through a heat seal machine. And this barcode will never be removed from fabric even after washing and dyeing. This software is very easy to operate and user-friendly. It comes with the most unique and essential features as per the requirements. It has a customized reporting system and an elegant theme. On top of that, this was built in the most professional way to serve your purpose.

PROKNIT

PROKNIT is a barcode enable fabric roll-tracking system for knitting and dyeing. It has 6 different modules/droplets like:-

Fabric Roll Tracking System - PROKNIT Modules:

Required Hardware

- Label press machine

- Barcode printer

- Mobile scanner

- USB scanner

- THINMED Label

- TTR Ink roll

- Dongle Key

- One server PC (RAM 16 GB)

- 4 Pcs normal desktop PC(configuration normal)

- TAB/PAD based on number of Inspection machine. One Tab for Grey Store

- Wifi at QC & Grey Store place.

“Combining a piece of thread with two needles into a piece of fabric” was an ancient concept of knitting. Today different methods and styles are used to knit fabrics. The origin of knitting is hard to trace but there is information about it. Some people believe that knitting started in Persia, others that were started in Palestine, Jordan, and Syria. Even some ensured that knitting grew out of the knitting of fishnets by men. In the 21st century, it has seen a resurgence of knitting, and this era gives birth to different types of knitting machines and products. In the last decade, People started using IC-controlled knitting machines as they offer huge advancement & automation facilities.

Like, an automatic knitting machine can produce much more work in a time frame, as it could make ten people’s output at the same time with the manual system. Really it brings a revolutionary change in the knitting industry throughout the world. Bangladesh particularly has experienced this change through the last decade. Many Bangladeshi manual sweater and pieces knitting machine has been thrown away replaced by automated one. The transformation has made Bangladesh’s knitting industry capable of delivering innovative design and quality production.

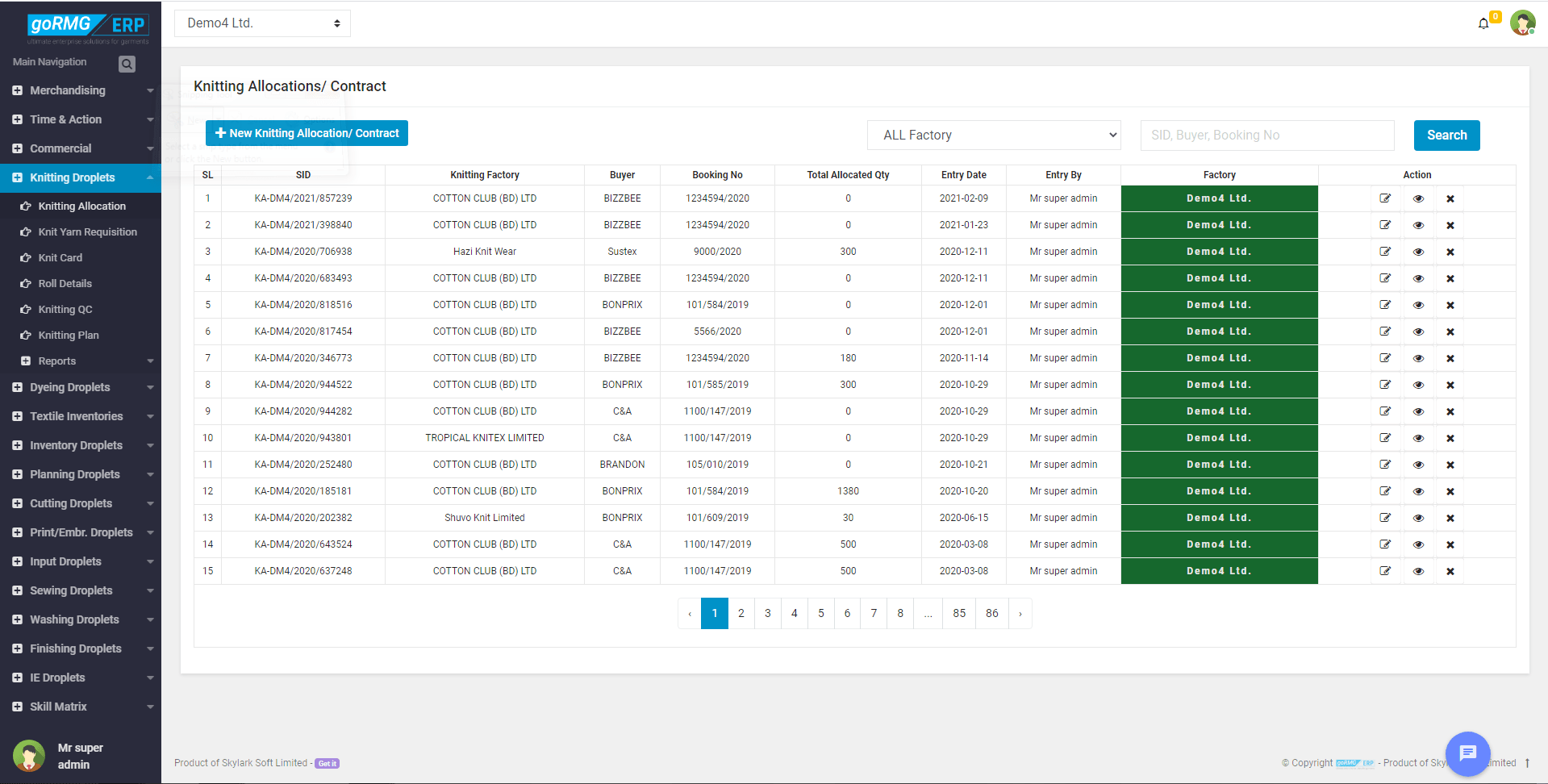

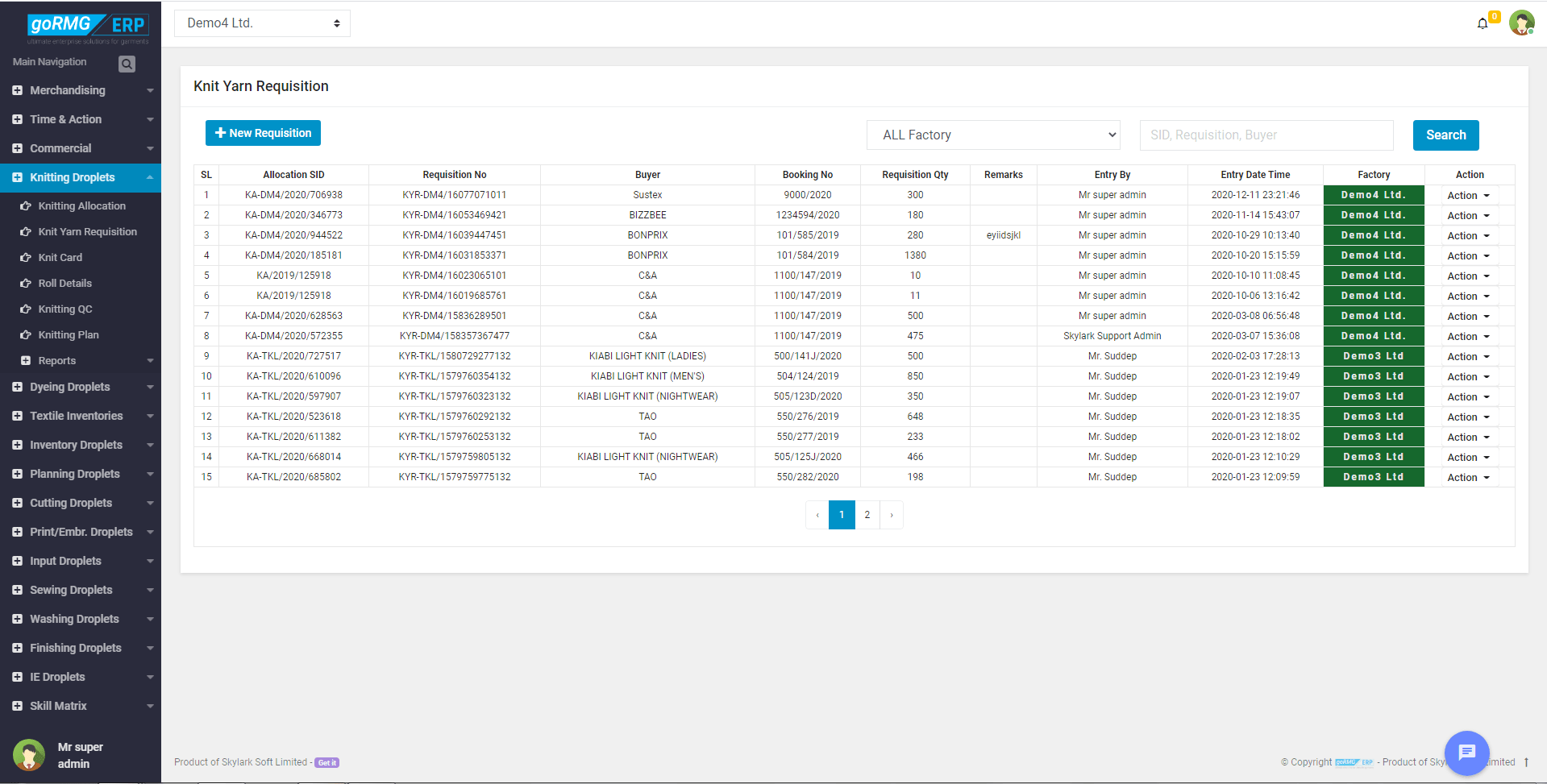

1. Order entry

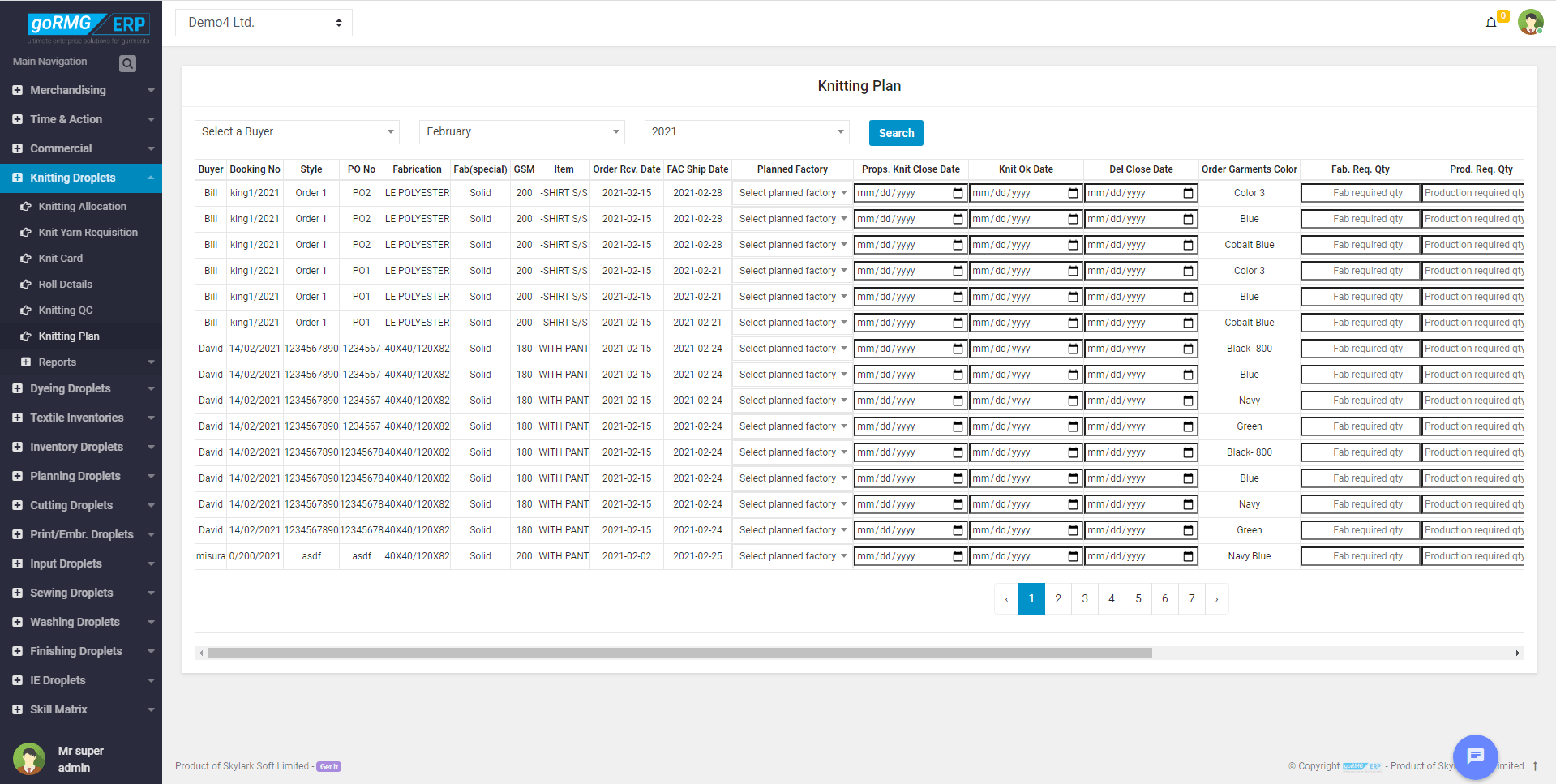

2. Knitting program

3. In house & subcontract production follow up

4. Automatic barcode labeling

5. Daily Production report

1. Instant QC without documentation.

2. 4 point grading system

3. Fault analysis report

4. Production analysis report

5. Daily QC/inspection report with sorting & filtering (i.e. Buyer wise/order wise etc)

1. Roll receiving & Delivering with barcode scanning.

2. Roll racking

3. Automatic Stock update

4. Auto bin card

5. Roll migration(Location update)

6. Batch delivery

7. Roll transfer (one’s buyer’s /order’s roll delivery for other order/buyer)

8. Roll splitting.

1. Receive finished batch

2. Weight checking roll to roll and batch to batch.

3. Finishing report

4. Receive finished batch

5. Batch to Batch compares (i.e. Roll weight, Actual Dia, Actual GSM)

6. Finishing report (batch wise)

7. Labeling finishing sticker automatically.

PROKNIT is mainly used in the Knitting Section. This product is nested in the Knitting Section of the Garments ERP System goRMG ERP, a widely used product for maintaining the ERP system of the Garments sector.